Garmin GNS 530

The Garmin GNS 530 has a larger, higher-resolution display than the smaller Garmin 430. Both are no longer in production but continue to be very common in general aviation aircraft.

This GPS is specifically designed for use with X-Plane 11.10 (or greater) and uses the screen-only popup instrument window feature to render the GPS screen on an HDMI display that is integrated into the assembly.

Parts List

| Component | Quantity | Source |

|---|---|---|

| Faceplate, hardware mount, mounting brackets | 441x120 mm | (Ebay) 3/16” bright white cast acrylic |

| 5-inch display I found it difficult to source a 5” display with a 4:3 aspect ratio and this one works perfectly. It is slightly smaller than the actual GNS 530 display but it is very clear and easy to read. |

1 | (Ebay) Innolux 5" ZJ050NA-08C 640x480 LCD w/HDMI controller board |

| Primary knobs Dual-rotary encoders are difficult to find. These are a bit pricey but are high quality encoders. I created the 3d printed knobs below specifically for these encoders. |

2 | (Desktop Aviator) 8mm Dual Rotary Encoder Switch w/Knobs & Mounting PCB |

| Push buttons These are a soft-feel push button with about 2mm of travel. |

14 | (Amazon) 7mmx7mm Momentary DPDT Mini Push Button Switch |

| Power/volume potentiometers With on/off and volume control. The 3d printed volume knobs below are designed for these. |

2 | (Amazon) 20K Ohm Dual Linear Taper Potentiometer Switch |

| Pan head screws Used for attaching the hardware mount to the rear of the faceplate. |

4 | (Amazon) #6-32 x 1/2” Phillips Pan Head Screws |

| Flat head screws For assembling the acrylic parts (holes should be countersunk before assembly). |

12 | #4 x 1/2” Flat Head Wood Screws |

Note The Amazon and Ebay links above are affiliate links and help me pretend that my hobbies are self-sustaining.

Faceplate

The faceplate is laser cut from white acrylic, painted black, and then laser engraved.

Hardware Mount

The hardware mount provides a layer for mounting the push-buttons and the display. I used acrylic for mounting the push buttons to simplify construction and to avoid having to create a circuit board. The push buttons are glued into the hardware mount.

Frame Mounts

The frame mounts are used to attach the assembly to the frame.

Frame Mount Brackets

The frame mounts are attached to the hardware mount with these brackets and #4 x 1/2” flat head screws.

The frame mounts also secure the display to the hardware mount and to the faceplate. A shallow 1/8” hole is drilled into the rear of the faceplate. The clips are designed to work with #6-32 x 1/2 pan head screws.

Electronics Mount

The electronics mount is used to attach the display electronics (HDMI controller board) and IO multiplexers to the assembly (more on the wiring coming soon).

Two 3d printed blocks are used for attaching the acrylic electronics mount to the frame mount brackets. The parts are attached with #4 x 1/2” flat head screws.

Display Bezel

A 3d printed display bezel frames the active pixels on the display is similar to the bezel profile on a real GNS 530.

Buttons

The GPS buttons are 3d-printed from white PLA, painted, and laser-engraved.

Small Buttons

Medium Buttons

Zoom Button

Flip Flop Buttons

Knobs

Dual-Rotary Knobs

The knobs for the dual concentric rotary encoders are designed to match those found on a real GNS 530 and are 3d printed from white PLA, painted, and laser-engraved.

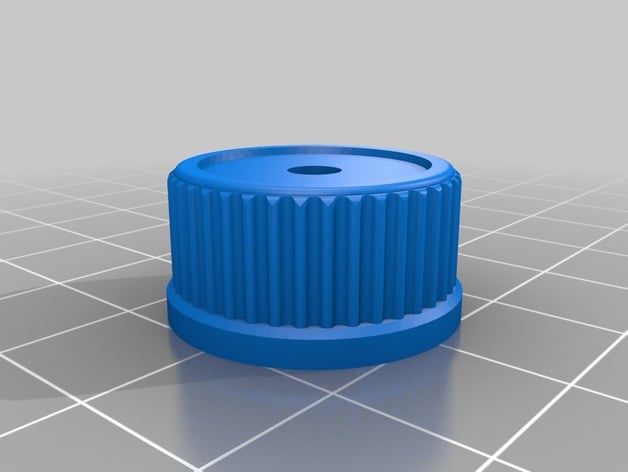

Volume Knobs

The knob is 3d printed from white PLA, painted, and laser-engraved.